The software for efficient assembly shop allocation

The software for efficient assembly shop allocation

Plan and optimize your shop allocation with AREAPLAN

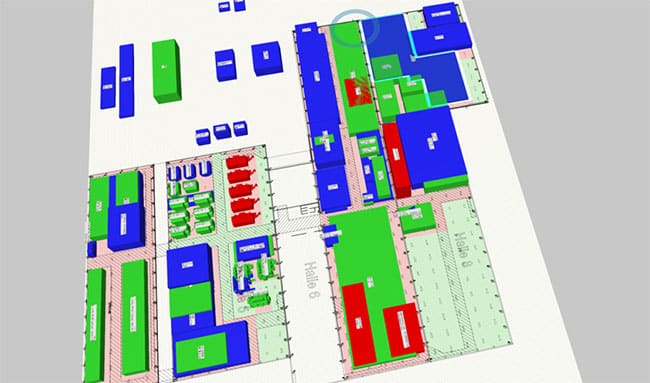

Create optimal space allocation plans for your assembly projects as well as production cells, production lines or entire production islands.

- Transparent, spatial and dynamic (also across plants).

- Determination of delivery dates or interim storage times

- Optimal utilisation of available space in the factory

Why you should rely on AREAPLAN for factory space planning

Efficient factory planning already starts with making optimal use of the available space in the factory. This is a particular test for production, assembly and workshop managers when large assembly projects with constant changes have to be planned in a limited space. In addition, restrictions such as construction height or area load must be taken into account. With AREAPLAN you digitise your space planning and create complete transparency about current and planned projects. As a result, you achieve more planning and investment security and increase throughput in the factory.

AREAPLAN as an ideal add-on to CAD, MES, APS and ERP

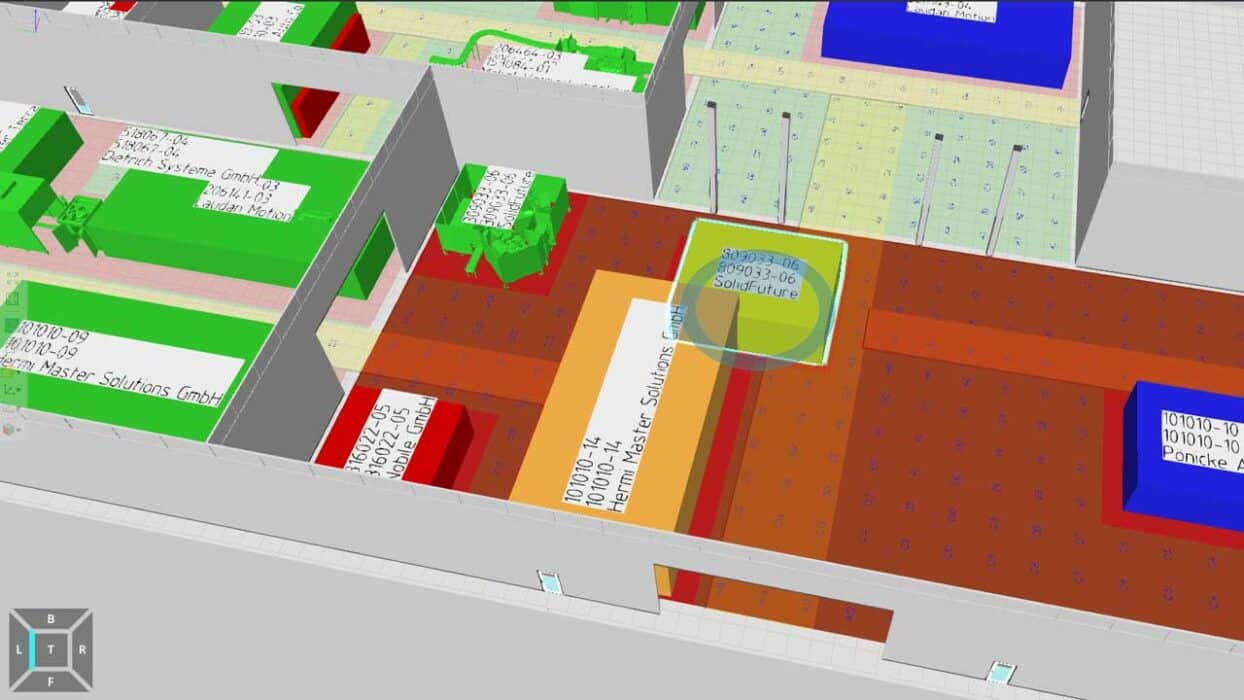

AREAPLAN is the perfect complement to CAD programs. Import CAD geometries and display your assembly projects or machine configurations over time. In addition, the area capacity planner can be seamlessly connected to upstream systems such as MES, ERP, APS or PMS. By constantly exchanging data, you ensure that all systems always have access to the latest data. You also improve the quality of your data through continuous and transparent production.

How you benefit from shop planning with AREAPLAN

- Better utilization of the available area in the assembly shop

- Greater transparency for all involved in assembly processes at the construction site

- Convenient area requirement planning in a dynamic 3D factory layout

- Allocating areas and scheduling sequences on a single platform reduces planning work

- Specific statements about project feasibility and delivery dates

Typical use cases: Where the use of AREAPLAN proves its worth

Efficient space capacity planning

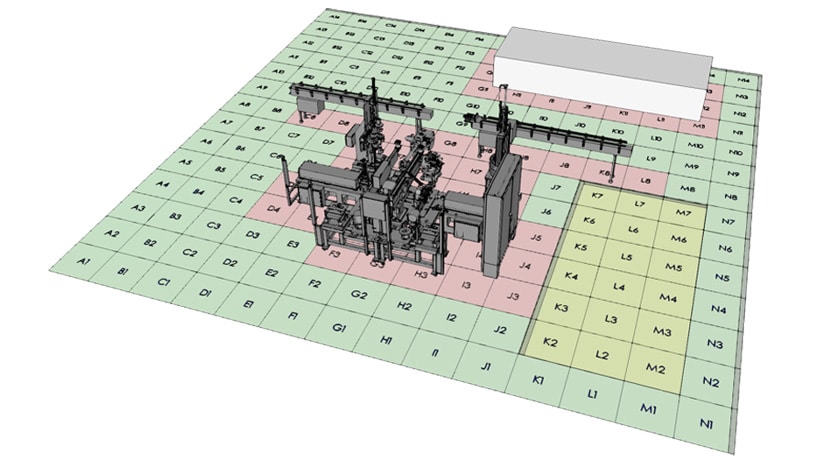

Machine builders are often faced with the challenge of setting up and testing equipment in their own factory halls before delivering it to the customer. With AREAPLAN you can immediately see when, on which area and over which period of time a project can be scheduled. Different machine layouts and nesting of machines can be taken into account.

Global plant planning at central level

With AREAPLAN, central plant planning for all locations can be carried out via the central planning department. Cumulate all projects such as production cells, production lines or entire production islands from all worldwide locations and see at a glance which projects can be implemented over which period in which plant.

Temporary storage in large-scale plant construction

Large products or components often require intermediate storage and need large storage areas before they are moved to the next processing station. With AREAPLAN you can plan large plants or large components efficiently on the available areas and see exactly over which period which large plant can be stored temporarily.

Why users appreciate AREAPLAN

Günther Redhammer

Team Leader for Parts Manufacturing and Team Manager for Component Manufacturing

FILL Gesellschaft m.b.H

"Everyday assembly planning and running through different configuration options has become much easier and clearer since the introduction of AREAPLAN. The strength in the solution is the improved project transparency for everyone. Future projects can be viewed over their complete time-frame. Any delivery delays that could affect the customer’s dead-lines are immediately highlighted, and clear for everyone to see."

Born to meet an application need

AREAPLAN was created in close cooperation with FILL, our long-standing customer and a Visual Components user. The solutions available on the market at the time were designed only for one-time setup of assembly and project shops, and the special machine construction company therefore sought out a suitable alternative. We jointly took on the task of solving this complex problem.

This resulted in a powerful, efficient and future-proof shop planning tool that can be scaled at any time to accommodate expansions and new buildings. Unlike conventional methods, the new shop planning tool can recreate the constant changes between diverse projects and simulate time sequences in addition to the spatial shop allocation.

Our market research showed that this tool perfectly fulfills the demands faced by other manufacturers of special machinery or producers of bulky products intended for assembly at the construction site. This was how our project-related shop planning tool gave rise to our new AREAPLAN product.

AREAPLAN functions at a glance

- Simple project planning in the area grid

- Traffic light colour schemes for project scheduling

- Immediate restriction check (collisions and warnings)

- Time slider selectable by days, weeks, months, time or time span

- Definition of project and hall properties

- Simple operation through drag & drop and 3D navigation in the factory layout

- Easy data export of the hall plan into a 3D PDF or of the frame data into Excel possible

- Statistics and reports on space utilisation

- Extensions as required, such as training, modelling of the hall layout or development of new, individual features

Take the next step!

More DUALIS solutions

-

3D factory simulation

Our 3D manufacturing simulation software lets you realistically plan, test and validate your manufacturing designs in a virtual setting.

-

Detailed order planning

Our intelligent Advanced Planning and Scheduling system enables rapid, automated and low-cost planning for all orders and resources.