Case studies

Learn how DUALIS solutions provide greater transparency, planning reliability and factory efficiency in companies of all sizes and sectors and how we have helped these companies implement solutions and adapt them to specific requirements.

- all

- AREAPLAN

- GANTTPLAN

- Visual Components

-

Download case study

GANTTPLAN Sucess Story: HakaGerodur AG

Find out more in the case study why HakaGerodur AG chose the advanced planning and scheduling system (APS) GANTTPLAN as a planning add-on to the ERP system from IFS and what advantages this brings for the leading manufacturer in the field of plastics extrusion.

-

Download case study

GANTTPLAN application report: Lübbering Group

APS meets ERP and workshop control: Read the user report to learn how the leading premium manufacturer of high-precision threading and drilling equipment shortens its tooling, production and lead times.

-

Download case study

AREAPLAN application report: FILL GESELLSCHAFT M.B.H

From pin boards with cut-out 2D layouts to 3D software for efficient area planning in the assembly shop: Learn how FILL uses AREAPLAN to double the efficiency of area planning, achieve significant cost savings and provide greater transparency for all involved.

-

Download case study

Visual Components application report: Dentsply Sirona

Read how the world's largest manufacturer of dental products and technologies uses the 3D simulation platform Visual Components to better validate product ideas and projects, increase throughput in production and achieve greater planning precision.

-

Download case study

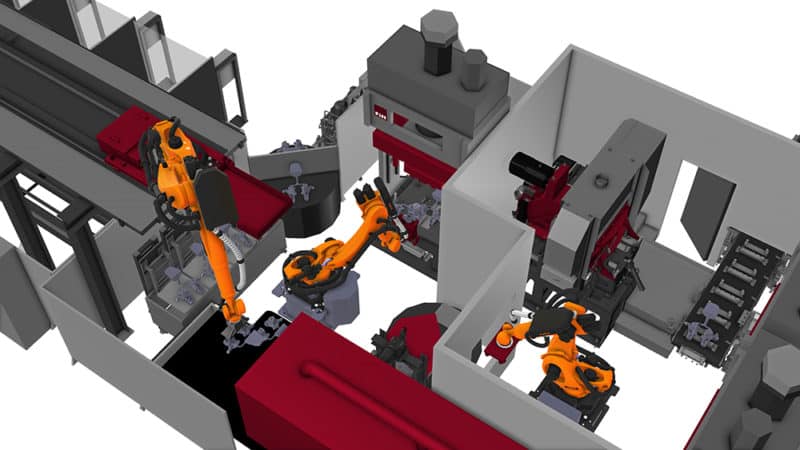

Visual Components application report: PIA Automation Austria

The automation technology specialist uses Visual Components to visualize detailed systems and load analyses. Ergonomics studies are also an essential part of project acquisition and implementation. Find out how PIA Automation works faster, more efficiently and more agile with 3D simulation and virtual reality.

-

Download case study

GANTTPLAN application report: STARLIM Spritzguss GmbH

Detailed planning, and silicone at its best: One of the world’s leading manufacturers of liquid-silicone technical moldings uses our innovative planning tool for automatic planning and optimization of injection molding operations in various plants. Learn how STARLIM employs GANTTPLAN to ensure transparency and a seamless flow of information in mass production.

-

Download case study

Visual Components application report: Faurecia Autositze GmbH

3D simulation at one of the world’s largest suppliers for complete seats: Learn how Faurecia uses the Visual Components 3D simulation platform to optimize material flows and designs more dynamic and flexible work flows by simulating them with AGVs.

-

Download case study

GANTTPLAN application report: EPflex Feinwerktechnik GmbH

Precise detailed planning for precision medical instruments: Read about how EPflex uses the GANTTPLAN APS system and ERP APplus from Asseco to optimize the planning of production systems while increasing on-time delivery performance by 20 percent.

-

Download case study

Visual Components application report: FILL GESELLSCHAFT M.B.H.

3D simulation in special machine construction: Learn how FILL uses the Visual Components 3D simulation platform to optimize plant design and avoid sources of error while improving internal and external communication.

-

Download case study

Visual Components application report: DALEX GmbH

Predictive 3D plant planning and advanced robot programming: Find out how DALEX, a specialist in complex manufacturing cells, saves time and money with the help of the 3D manufaturing simulation plattform.

-

Download case study

Visual Components application report: KraussMaffei Automation GmbH

One of the world’s leading manufacturers of plastic and rubber production and processing machines works multi-dimensionally when it comes to automated injection-molding processes. Learn how KraussMaffei uses the Visual Components 3D simulation platform to shorten commissioning throughput times and achieve more reliable planning.

-

Download case study

Visual Components application report: Kewesta Fördertechnik GmbH

Kewesta simulates “Power & Free” with Visual Components. Learn how one of the leading providers of conveyor, drive and chain technologies used the 3D simulation platform to improve on-time delivery performance by up to 70 percent and reduce the plant planning risk by up to 80 percent.

-

Download case study

GANTTPLAN application report: Frauenthal Group

Read about the Frauenthal Group’s successful use of GANTTPLAN OE for daily order scheduling and optimization.

-

Download case study

GANTTPLAN application report: Galfa GmbH & Co. KG

Thanks to networked planning, Galfa is well prepared for Industry 4.0. Read how the high-performance coating company for functional coatings in the fields of cathodic corrosion prevention and thread locking achieves greater transparency across all work steps and optimizes throughput times.

-

Download case study

GANTTPLAN and Visual Components application report for Futuresim: Solarlux GmbH

Industry 4.0 in practice: Optimized production planning in surface technology—combination of the Visual Components 3D product suite and the adapted GANTTPLAN algorithms from DUALIS in the FUTURESIM Pro master computer system. Read more in the user report.

-

Download case study

GANTTPLAN application report: Kurt Zecher GmbH

It’s all about trouble-free processes in the production of printing rollers at Kurt Zecher. Zecher chose the GANTTPLAN detailed planning software to ensure ideal scheduling, early detection of load peaks and better control of production area utilization.

-

Download case study

GANTTPLAN application report: Feingerätebau K. Fischer GmbH

Fischer specializes in precision weather data measuring and recording instruments. The company uses the GANTTPLAN detailed planning software to ensure that production planning is just as precise as its products.