COMPLEXITY MADE EASY

35 Years of Know-how

Driven by a passion for mathematical optimization, we’ve developed smart solutions for the smart factory – solutions that deliver real value, clarity, and customer satisfaction. By combining deep product and market knowledge with comprehensive services, we offer complete, tailored packages to meet your needs.

Pioneering technologies

We’re committed to innovation, constantly exploring new ideas and technologies like AI to enhance our software solutions. Our active involvement in pioneering research projects ensures your production stays ahead of the curve.

Even stronger together

As a subsidiary of iTAC Software AG and part of the DÜRR Group, we offer ideal conditions for integration and connectivity in the smart factory. We also work with a strong network of partners and provide platforms for collaboration and exchange.

portfolio

Digital tools for smarter production

-

GANTTPLAN

Production planning and optimization

Our intelligent Advanced Planning and Scheduling system GANTTPLAN enables rapid, automated and low-cost planning for all orders and resources.

-

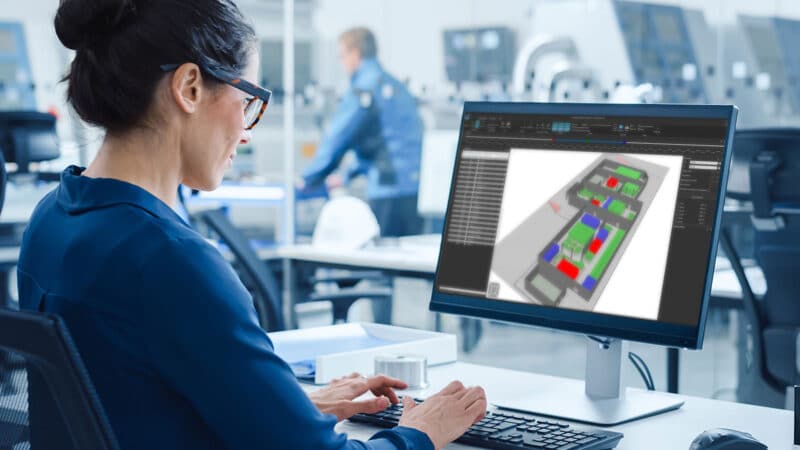

VISUAL COMPONENTS

Manufacturing simulation and robot offline programming

With Visual Components and our Add-ons, you can simulate, test, and optimize your production processes and robot operations in a virtual 3D environment – helping you make confident decisions before anything goes live on the shop floor.

-

AREAPLAN

Smart space planning for assembly and manufacturing

AREAPLAN helps you digitally plan and optimize your assembly and production space – giving you real-time visibility, flexibility, and control over your layout, so you can respond quickly to changes and make the most of every square meter.

references #success stories

What our customers say

-

Sven Worm

Vice President New Markets, Columbus McKinnon (CMCO), to which montratec belongs -

Christian Dewald

Vice President Corporate Supply Chain Management, WAGO GmbH & Co. KG, WAGO GmbH & Co. KG -

Christiane Franke

VP Logistics, WITTE Automotive GmbH -

Karsten Budach

Principal Engineer Sales & Business Development, Fabmatics GmbH -

Tobias Tönnies

Managing Director, Johannes Lübbering GmbH -

Nikolaus Szlavik

Managing Director, PIA Automation Austria GmbH -

Günther Redhammer

COO, FILL Gesellschaft m.b.H

Get a deeper insight

Our specialists will take you through your DUALIS solution. 60 to 90 minutes is all the time you’ll need to learn about the comprehensive options available. If required, we can adapt the live demo to your specific requirements. Why not register for a free product demo now.

DUALIS NEWS

The latest from the press

Our upcoming EVENTS

Experience live what planning can achieve

DUALIS Portrait

DUALIS GmbH IT Solution was founded in 1990, and is now a subsidiary of iTAC Software AG. Dualis specializes in software development and delivery of services for production planning and factory optimization. The product range includes the detailed planning tool GANTTPLAN, area planning software – AREAPLAN, and the 3D simulation platform from Visual Components. The products are used in numerous large-scale industrial applications, medium-sized company operations, and in the general production and service sectors.

Since 1990, DUALIS GmbH IT Solution has been your partner for agile and efficient production. As part of the iTAC Software AG and the DURR Group, we deliver a full suite of software solutions and consulting services designed to optimize your manufacturing processes. From production planning and scheduling with GANTTPLAN to intelligent space optimization with AREAPLAN and immersive 3D factory simulation with Visual Components, our tools empower businesses across industries to achieve peak performance.