The 3D manufacturing simulation software

The 3D manufacturing simulation software

Plan your factory of the future with Visual Components

Design and validate your manufacturing concepts and production facilities with 3D factory simulation software and DUALIS add-ons.

- Simple, virtual and powerful

- For more transparency and throughput in production

- Software, consulting and services from a single source

Why you should use Visual Components for factory simulation

Visual Components is one of the leading and most powerful factory and robot simulation software on the market. And there are many reasons for that:

One platform for all simulation tasks

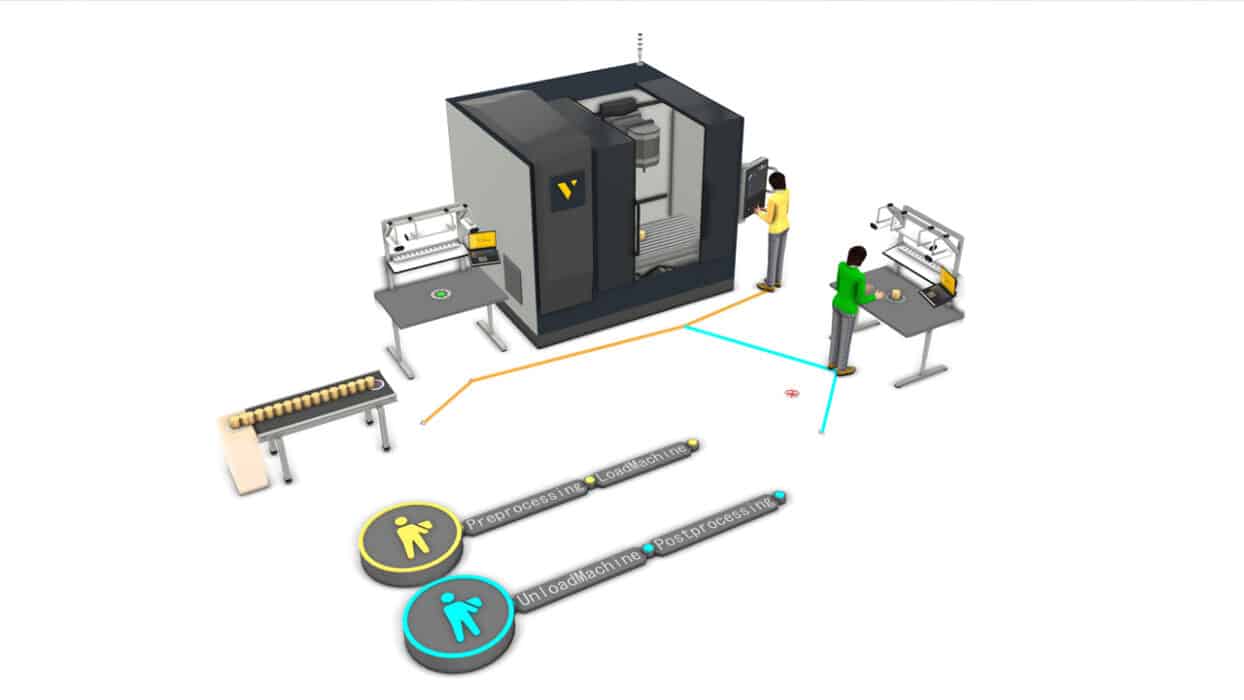

The 3D simulation software Visual Components can be used in many different ways. Common areas of application are:

- Plant planning

- Layout planning

- Virtual commissioning

- Digital twin

- Material flow simulation

- Robot simulation

- Robot programming / Offline programming (OLP)

Cost-effective and quick start

With three expansion levels and a flexible licensing model, Visual Components is scalable and can grow with your requirements. A 1-2 day basic training course by DUALIS also ensures that you get up to speed quickly. This allows you to start small, achieve results quickly and, if required, upgrade to a higher expansion level at any time, purchase further licences and/or add further DUALIS services.

Over 3,000 factory components

With more than 3,000 pre-built, simulation-ready factory components, the Visual Components eCatalog contains an extensive library of virtual models with over 1,600 robots from more than 70 manufacturers, and a wide range of conveyors, machines, production equipment, robot accessories, factory equipment and more. This allows you to design your any manufacturing layout virtually and in great detail.

High-resolution image and video material

With Visual Components you can prepare professional quotation and marketing documents in 3D by simply exporting and integrating the 3D simulations created in the form of high-resolution images, videos or animations. This allows you to present complex interrelationships in a visually appealing way and convince your customers with a unique presentation of their capabilities.

Permanent further development

The 3D simulation software is continuously developed further. Thus, with 1 to 2 releases per year, new and sought-after functions are regularly available to users.

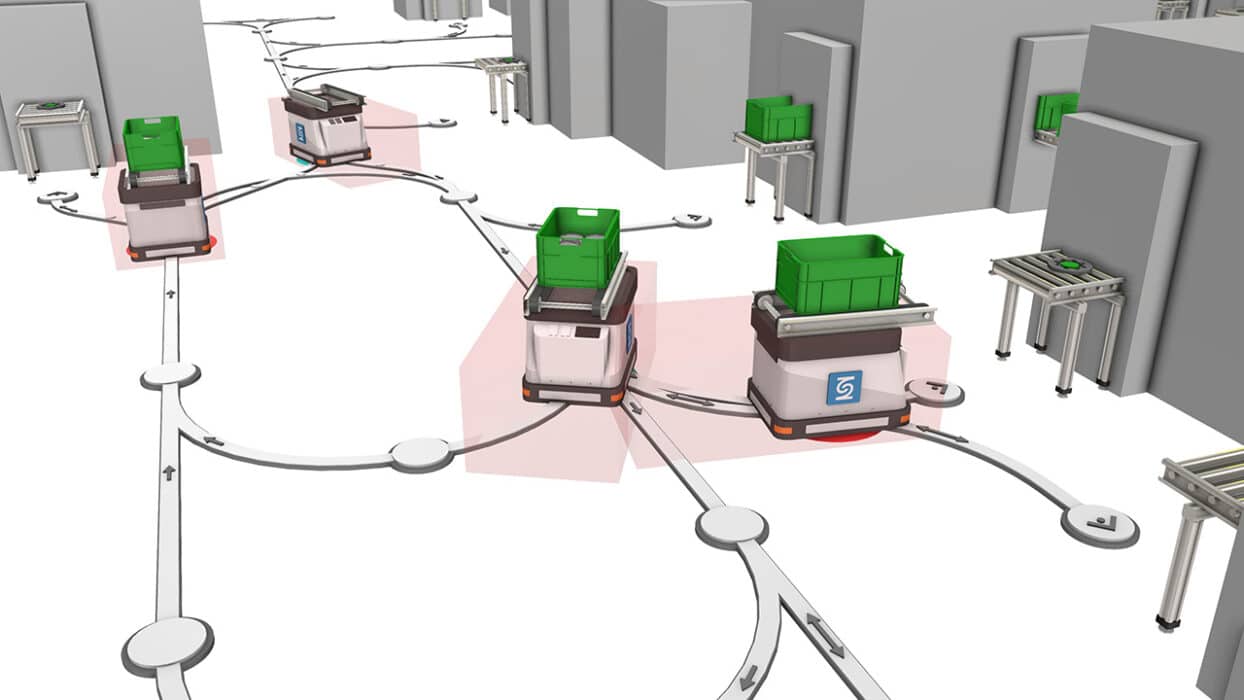

In addition, we are constantly developing new add-ons that are compatible with Visual Components, with the aim of perfectly complementing and further simplifying the application. With our Statistics Module, for example, you receive a much more detailed evaluation of your simulations or, with the support of our AGV library, you can plan driverless transport systems better, simulate them in greater detail and evaluate them more efficiently.

Usable across departments

The application of the Visual Components 3D simulation platform is particularly suitable for:

- Technical sales

- Project planning

- Engineering / construction

- Robot programming (OLP/OEM)

By accessing existing work results across departments, planning and simulation experts can significantly reduce their workload. This saves costs and time in the project and in ongoing operations.

How you benefit from 3D simulation

Nikolaus Szlavik

Managing Director

PIA Automation Austria GmbH

"We chose Visual Components because the solution can be used flexibly and offers a user-friendly interface and a large library. We were also convinced by the open design options for our own add-ons as well as the permanent further development, which is reflected in regular updates. Despite the innovative nature of the product, the sales partner DUALIS with its own add-ons, library and intensive customer support also tipped the scales."

What our users say

More than 2,400 companies from the manufacturing industry worldwide already rely on Visual Components’ solutions for the planning and simulation of their manufacturing concepts. In combination with our know-how in the implementation of the software, our useful add-ons and individual adaptations, our customers achieve even more transparency as well as planning and investment security. This results in error reduction as well as time and cost savings in project planning and ongoing operation.

The Visual Components product family: flexible and scalable

The perfect solution for your specific needs

No matter for what purpose you want to use Visual Components the product family offers the right expansion level for your specific needs. The 3D simulation platform was developed specifically for the production industry and is based on an efficient, flexible and scalable platform. This allows you to start small, achieve results quickly and grow successively with your simulation projects.

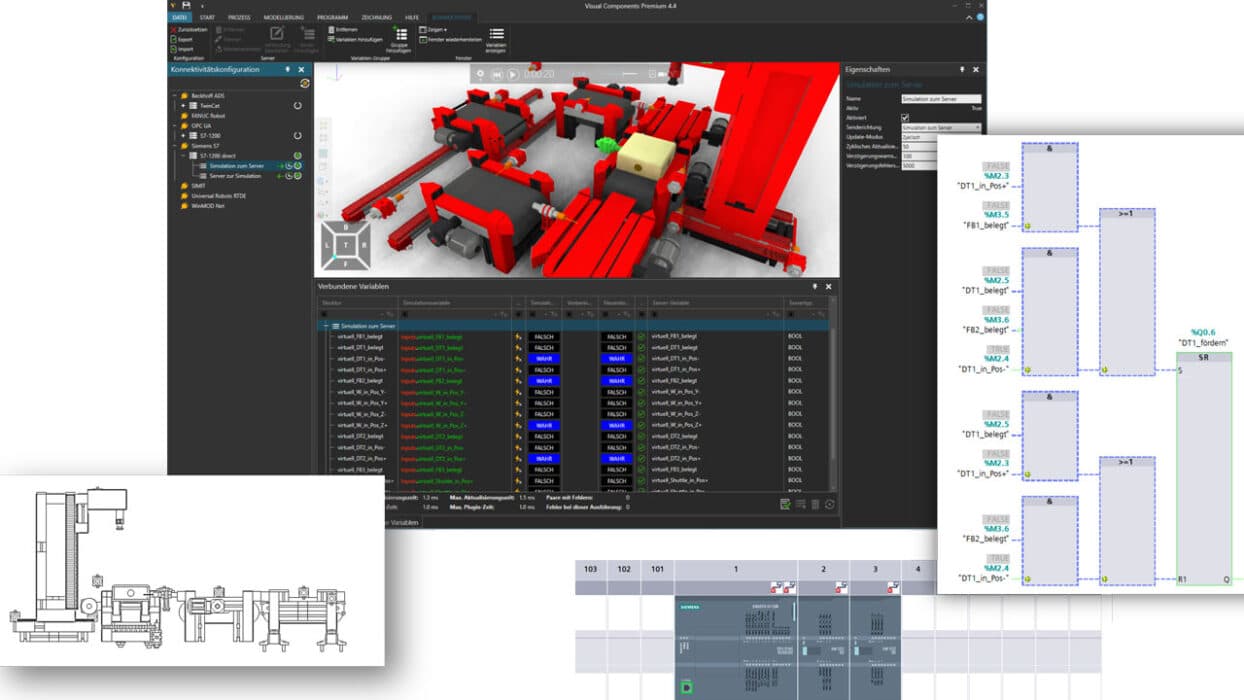

Visual Components Essentials is the basic platform with an extensive library of existing and configurable components. With Visual Components Professional you can also model your own components. And the all-in-one solution Visual Components Premium offers you additional functions for advanced robot programming and virtual commissioning.

Visual Components expansion stages

Visual Components Essentials

Design, plan and simulate your future factory with a catalogue of prefabricated factory components:

- Basic robot programming

- VC Experience on the smartphone

- Basic virtual commissioning

- Creation of sales content

- Virtual Reality

Visual Components Professional

Define and create your own factory components for 3D factory simulation.

- All Essentials functions

- Convert CAD data into simulation models

Visual Components Premium

Design your entire factory virtually

- All the features of Essentials and Professional

- Optimised virtual commissioning

- Advanced robot programming

- Interactivity and VR

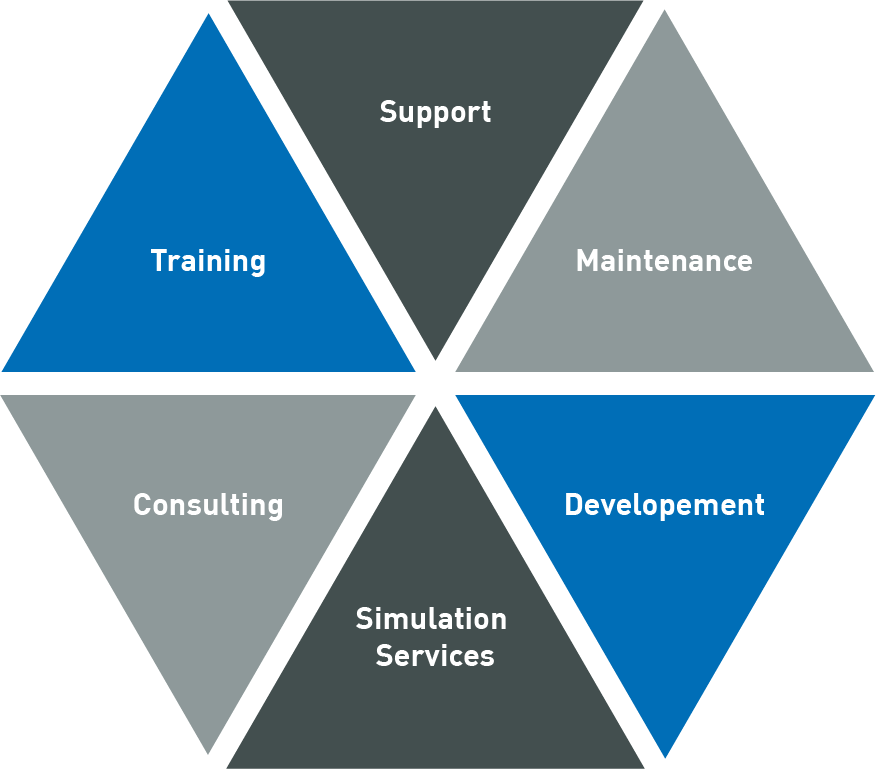

How we can support you with your simulation tasks

Experienced and authorised Visual Components Reseller with the PLUS

We have been working successfully with the manufacturer Visual Components since 2006 and act as an authorised reseller (Value Added Reseller). With around 100 simulation projects and training courses per year for companies of different sizes and industries, we have unique integration expertise for the 3D simulation software.

We offer the complete package: software, service and advice from a single source

We make you fit for the efficient use of the software in trainings, support you in the conception of your simulation solutions and advise you individually on your questions. If required, we develop individual manufacturing solutions for you and offer you useful add-ons that are compatible with Visual Components.

Take the next step!

More DUALIS solutions

-

Detailed order planning

Our intelligent Advanced Planning and Scheduling system enables rapid, automated and low-cost planning for all orders and resources.

-

Area planning

Our planning software for digital shop allocation helps you make the best possible use of limited areas in the assembly shop.