-

Presse

/

03. April 2024

DUALIS space planning tool increasingly used for centralized plant line planning

-

-

Plan optimal utilization of available factory space across all plants

- Increasing use of AREAPLAN in the automotive sector

- Optimal scheduling of production lines over a longer period of time and all locations

- Utilization reports support decisions on distribution to locations, site expansions or the establishment of new production locations

- More transparency and easier handling thanks to new functionalities

Dresden, March 22, 2024 – In many industries, such as the automotive sector, new production lines or expansions of existing lines in plants are not planned ad hoc, but over a longer period of time. Systems that create capacity utilization reports help planners to better assess whether the existing space is sufficient or whether measures such as distribution to other plants, site expansions or new production locations are required. This is done by the AREAPLAN space planning tool from DUALIS GmbH IT Solution, which is increasingly being used for global plant line planning at central level.

For efficient factory planning, it is essential to make optimum use of the available space. This often puts production, assembly and workshop managers to the test. This is especially true when, for example, large assembly projects with constant changes, several production lines over a certain period of time or large-volume products with high space requirements have to be planned in a limited factory space. With AREAPLAN, DUALIS offers software that enables cross-plant planning of space allocation in assembly and production halls. Utilization reports support the decision as to whether sites should be expanded or new ones built.

Ralf Dohndorf, Vice President Factory Simulation at DUALIS, explains: “Our manufacturing footprint software AREAPLAN provides transparency about current, planned and completed manufacturing and assembly projects. It is the first and only tool on the market that allows users to digitize and optimize space allocation both spatially and over time across all plants. We have noticed that the space planning tool is no longer just being used for individual locations, but increasingly for global plant line planning at a central level.”

Global plant planning in just one tool

AREAPLAN is constantly being further developed in close cooperation with users. This is also reflected in Release 3.9. It offers various new functions to make the planning of assembly projects or production lines even more efficient.

“With AREAPLAN, global plant planning can be carried out for all locations via the central planning department. This means that projects such as production cells, production lines or entire production islands can be cumulated from all locations worldwide. The new functions make it even easier to see which projects can be implemented in which plant over which period of time,” says Ralf Dohndorf.

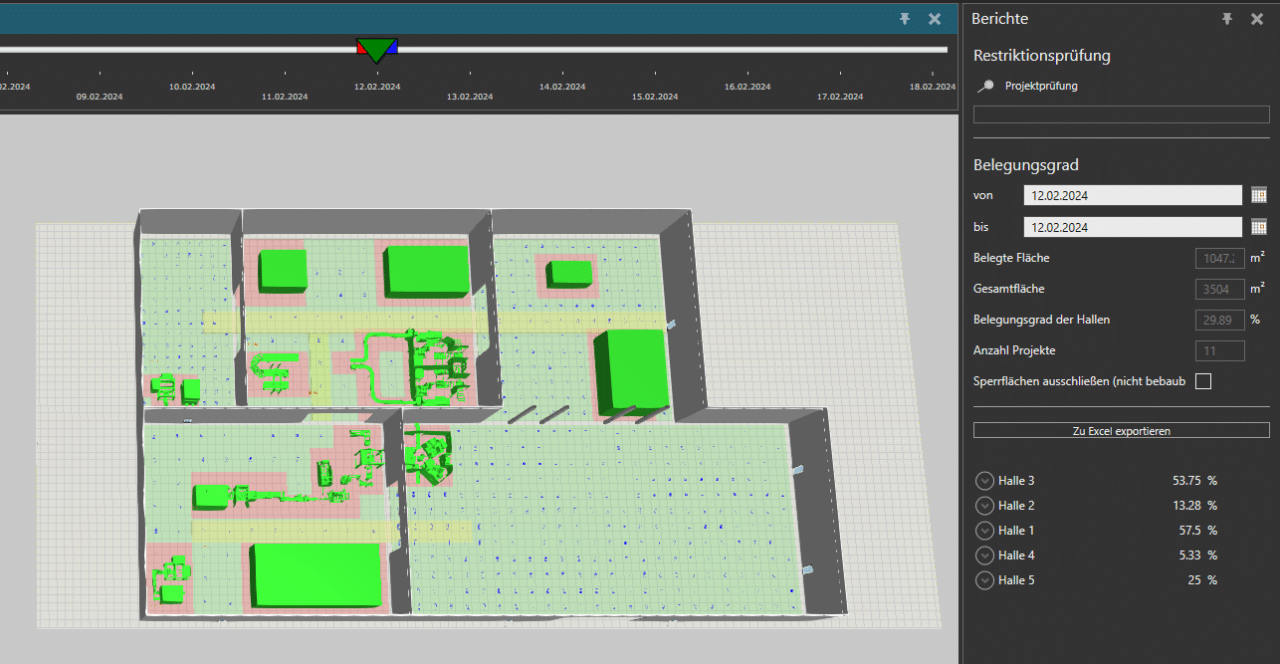

With the new release of the software, capacity utilization can now be broken down into individual sub-areas – for example in halls 1 to 5 or according to hall categories such as pre-assembly and final assembly. The breakdown can then be exported to Excel and the time period can be freely selected. The space utilization can also be displayed in colour in a three-dimensional block diagram. Higher positioned areas mean higher utilization and are also marked in color. This means that the darker and higher the areas, the higher the utilization in the selected time horizon.

AREAPLAN: Capacity utilization by hall AREAPLAN: Space utilization in 3D layout A new search function in the project and order list helps planners to find a project more quickly and maintain an overview. Release 3.9 also offers other new functions such as configurable color schemes, improved evaluation options for space utilization, a selection aid and support for the documentation of projects through project-related notes.

Ralf Dohndorf summarizes: “Companies can synchronize their IT landscape for global plant planning in just one tool. Several employees work centrally on one platform. This creates a uniform database and one hundred percent transparency for everyone involved. This has a significant impact on planning quality.”

You can find out more about AREAPLAN on our product page or in a personal live demo. In just 60 minutes, we will give you an insight into the area planning tool and find out together how AREAPLAN can help you to efficiently plan production and assembly projects across all plants.