-

Presse

/

16. May 2024

HOMAG uses AREAPLAN from DUALIS for space capacity planning in special machine construction

-

-

Better planning and optimization of assembly area occupancy

- Construction of around 650 machines per year causes high and changing space requirements

- AREAPLAN replaces problematic area planning using Excel

- AREAPLAN enables comprehensive area planning: import order list, project generation and machine scheduling on the assembly area

- Positive effects such as improved forecasting capability noticeable after just a short period of use

- Automated data exchange with SAP via MES/MOM planned for the future

- AREAPLAN has now been rolled out to other HOMAG sites

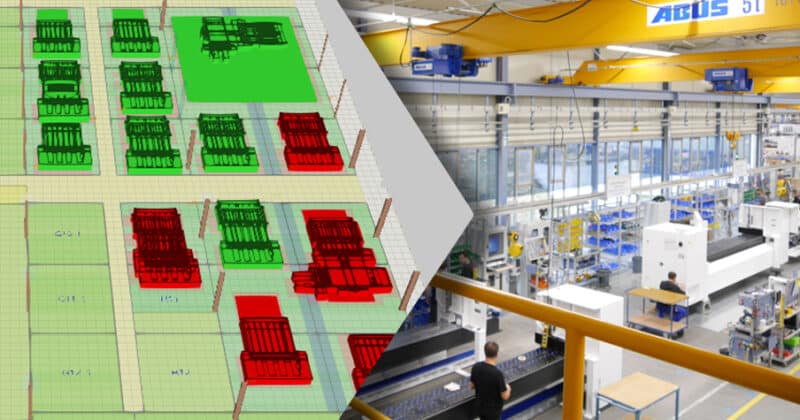

Dresden, xx. May 2023 – The production and assembly of special machines needs to be well planned – also in terms of the space required. A limited assembly area can quickly become a critical bottleneck. In addition, varying delivery, assembly, commissioning and disassembly times as well as restrictions such as height and crane loads must be taken into account. DUALIS GmbH IT Solution has therefore developed the AREAPLAN software for digital hall planning. HOMAG Group AG uses the solution at various locations for area planning in assembly, replacing the manual Excel solution.

The HOMAG Group, a subsidiary of the Dürr Group, is a manufacturer of machines and systems for the woodworking industry and trade. The company has a 30 percent share of the global market and around 7,000 employees. Machines for furniture and construction element production and timber construction are manufactured at 14 locations.

HOMAG Plattenaufteiltechnik GmbH in Holzbronn is also part of the group of companies. At this site, panel dividing saws are manufactured for the furniture industry, from standard machines to special machines. These require different area allocations during assembly.

Excel gives way to a digital area planning tool

“We build around 650 machines a year at the Holzbronn site. We therefore have a high and changing space requirement in assembly. A small machine is already five to six meters wide and can reach four to five meters in length. The assembly areas therefore need to be carefully planned. Previously, the area planning was done manually in Excel, but this caused various difficulties,” explains Matthias Heldmayer, Assembly Manager at HOMAG Plattenaufteiltechnik GmbH.

In Excel planning, the available area was divided into predefined squares, which meant that the various machine layouts could only be mapped inadequately. Also, no collision warnings were displayed. And data had to be manually maintained and constantly checked.

“Is the machine still standing or has it been dismantled in the meantime? When is it expected to be dismantled? Was another machine scheduled for later, which now has to be moved again because the area is still occupied? In the past, we were constantly faced with these kinds of challenges,” says Matthias Heldmayer.

The AREAPLAN planning tool for plant areas replaced Excel and now takes care of area planning – from creating and loading the order list to generating a project and scheduling the machines on the assembly area.

Gut feeling gives way to concrete forecast

By using AREAPLAN, the assembly areas can now be planned and utilized more efficiently. For example, the tool allows the machines to be nested based on the machine layout. Matthias Heldmayer says: “The first positive effects were noticeable after just a short period of use. AREAPLAN is now an integral part of our assembly area planning. For example, we can now reschedule much more quickly and transparently if a part cannot be delivered on time. The quality of the data has also improved significantly since the introduction. Added to this is an improved ability to forecast machine scheduling in the future. Whereas it used to be a gut feeling, we can now forecast area availability very precisely.”

Currently, the order data is loaded manually from SAP into Excel and then imported into the AREAPLAN software. AREAPLAN automatically recognizes changes such as the time period, displays corresponding information and updates these values in projects that have already been scheduled. In future, data transfer is to be automated via the MES/MOM of iTAC Software AG so that AREAPLAN always has access to the latest data. The assembly hall area planned with AREAPLAN is then to be imported back into SAP.

Ideal utilization of spatial and temporal degrees of freedom

The project started in 2022 at the Holzbronn site. AREAPLAN was initially used here and was later rolled out to other locations.

Jens Held, Vice President Operations at HOMAG Plattenaufteiltechnik GmbH, reports: “Some sites now work exclusively with AREAPLAN. The area planning tool can be customized for specific projects. It supports the ideal utilization of our spatial and temporal conditions. Future projects can be viewed at any time via a timeline. Statements regarding delivery dates are therefore more reliable and transparent. A planning tool that thinks in several directions – a great relief for us.”

You can find more information about AREAPLAN on our product page